Design of complex foundry patterns and moulds including; blown, fully ejected Laempe core boxes, shell core boxes and gravity dies.

- Experience of Iron (including SG), Aluminium, Steel and Magnesium foundry processes

- No mould design is too complex for us to undertake

- Sensible, practical core splits and print designs to ensure accuracy and repeatability

- Happy to provide supporting documentation and work instructions for the foundry or even attend for complex trial builds

- Experience in sand casting (including petrobond), gravity dies and ceramic cores

Thanks to our reverse engineering and casting design experience we can undertake casting development and casting replacement projects. We can help you if you;

- have a broken casting and in need of an urgent replacement

- wish to develop historic castings for the spares market

- have a new project that you’d like input on casting design

- want to move away from a fabrication to a casting to reduce costs

- need to develop an existing design into a new design or application

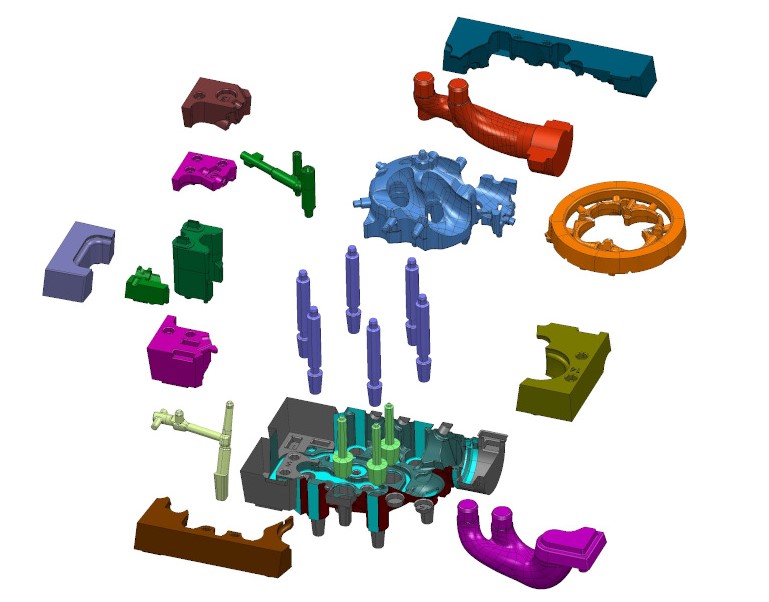

A foundry mould pack with more than 20 cores

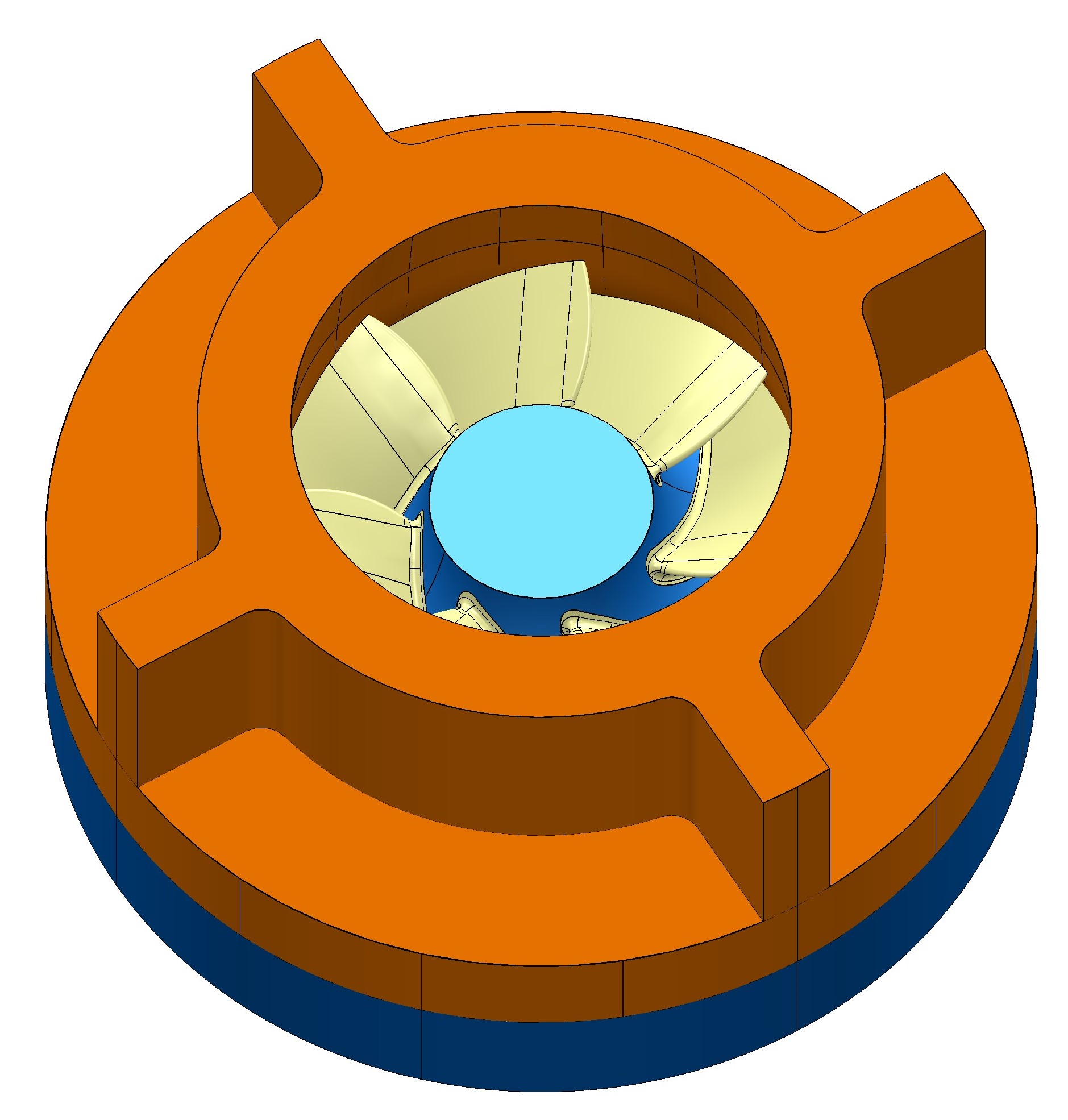

There’s an impeller pattern and core box design (complete with loose pieces) available to download on my GrabCAD profile;

Just follow this link: https://grabcad.com/library/impeller-casting-pattern-equipment-design-1

Interested in learning more? Please use the contact form here or call Matt on 07758 242615.

Freelance CAD Design Services, Derby UK

Engineering | Automotive | Motorsport | Aerospace | Composites | Castings | Foundry | Fixtures | 3D Printing | CNC | Product Development